The machines that we provide ended up made for amenities needing fast established-up, relieve of operation, and high dependability in lower to medium volume pick & place purposes.

The oven usually has various zones, which can be separately managed for temperature. We provide benchtop batch solder reflow oven to computerized ground style devices.

The computer software is useful for producing offline programming of computerized SMT machines. By doing this, it is going to simpler to derive elevated effectiveness and throughput from your machine.

The speed at which the select-and-spot machine works is very important. You wish to look at this primary before every other issue because it is one of the significant options that make the SMT machine function mainly because it must.

Scorching Bar soldering, also known as pulse heat thermode or pulse bonding, is used to be part of two sections with each other by melting solder concerning them to kind a permanent electromechanical bond. The head to melt the solder is generated by thermode’s resistance to electrical latest. $four,five hundred.00

One more unique attribute of the DDM Novastar decide-and-position machines is different stages which have been utilized to automate the workings on the machine.

These levels of automation really have to do with the several generation stages and abilities from the DDM Novastar SMT machines.

M10 Direct no cost Reflow oven is specifically suitable for mid-large quantity output. 10 upper and ten base pressured hot air convection zones allow good quality lead-cost-free soldering with uniform heating and Excellent method steadiness Temperature accuracy of ±one°C, ensure the finest temperature Management over the Printed Circuit Board Assembly

We are not talking about just one machine. Up to six (6) machines are used to aid the placement of electronic parts about the circuit boards.

Larger throughput SMT reflow oven with twenty" (508mm) vast conveyor for creation runs. The 2000HT scorching-air reflow procedure makes use of our patented Horizontal Convection Heating technology with electronic temperature controls for very uniform air circulation and temperature profiling through the board – offering enhanced approach control.

Over the past decade, these machines have shown Remarkable security and dependability in Procedure. Consequently, Chinese-made placement machines now offer An impressive Charge-general performance ratio, generating them one of the most feasible and economical option for new factories looking for smd assembly machine to equilibrium high-quality and affordability.

The machine does not only uncover the defects or faults inside the circuit board. It is additionally utilized to repair or take care of All those defects.

Our center on precision, adaptability, and quality makes certain trustworthy PCB assemblies, from prototypes to significant production volumes Get in touch with us today to discuss your project and explore the Adonai benefit!

The SMT machines dispersed by Panasonic also are adaptable. You may get machines for the two entry-stage plus more complicated requirements.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Michelle Trachtenberg Then & Now!

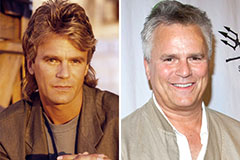

Michelle Trachtenberg Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!